V belt speed fpm 12 Driver RPM Driver Pitch Diameter in π. To calculate the total load inertia of the motor shaft conversion value.

Pulley Belt Calculations The Engineering Mindset

V-BELT DRIVES This technical manual contains all important technical information and methods for the design and calculation of drives with Optibelt V-belts and V-grooved pulleys for industrial applications.

. The following equations will determine. International Organization for Standardization IS0. To calculate belt length enter size of.

Belt drive power transmission. Ht Height of the tooth on the belt. This approach is only valid for electric engines and Poly V belts.

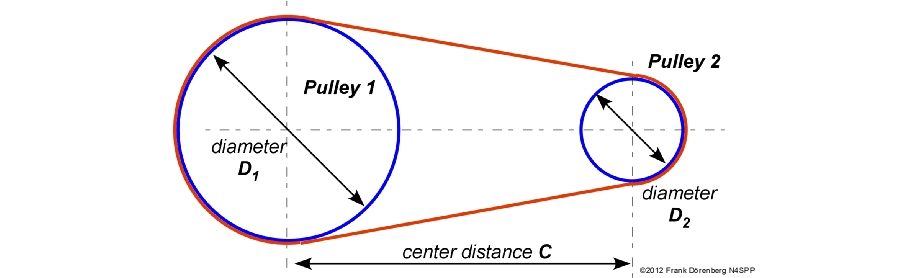

C Center Distance. Tb Thickness of belt measured from tooth valley to the flat side of the belt. Pd design power as determined in Section 311 W belt weight per foot of length lb.

To meet all the expectations of the market Hutchinson has expanded its product portfolio with a range of Hutchinson V-belts timing belts and pulleys. Dpo Outer Diameter of pulley. This software will run on your local PC with installation.

Belt tension load T 2 T 1 T 2 T 1. Belt speed v π D 1 n 1. The v-belts are made of rubber with fabric cords to transmit power and its covered with a protective layer.

Belt speed feet per minute d. See Table 2 below for typical values. The belt tensions are reduced by mv 2 so that.

The preferred center distance is larger than the largest pulley diameter but less than three times the sum of both pulleys. WebCAP can be used for simple 2-pulley v-belt drives to design for optimal efficiency or to calculate proper tension values. Effect of centrifugal force.

Click on the link above to go to the WebCAP site. N Number of teeth on pulley. FIRST APPROACH FOR ELECTRIC ENGINE.

Divide the design power with the corrected power rate of the v-belt. These calculations are mainly for existing installations but you could also put it towards your design if you want to calculate what the length needs to be of the belt as long as you already know the distance between the two pulleys and the size of the pulleys. To calculate multiple pulley sets where the first driven large pulley shaft drives the second driver small pulley and so on enter Initial Small Pulley RPM Number of Sets and Small Diameter Large Diameter and Centers of each Set below.

RPM of small sheave Power HP Pe x V 33000 HP. In this video we learn how to calculate the belt length as well as the distance between the two pulleys This is common in the HVAC and building services indu. Belt speed feet per minute Torque Tq Pe x d 2.

Optimal speed range is 10007000 ftmin 3002130 mmin. The number of cords are increased based on the force requirements. All the page number talked about are from Design Data Book.

V-belts need larger pulleys for their thicker cross-section than flat belts. IS0 4183-1989 Belt drives - Classical and narrow V-belts - Grooved pulleys system based on datum width. Effective friction coefficient μ μsinβ2- Ratio of belt forces T 1 T 2 expμα- Belt tension load T 1 T 1-T 21-T 2 T 1 N.

Speed Ration Arc of contact Tension ration for belt about to slip Power Capacity Pulley Torque Initial Tension. The rubber layer transmits the force in cord to the side layers. For example if you found 271 you must use 3.

Horsepower HP Tq. V-Belt Pulley Design Calculation. Hutchinson develops and manufactures complete power transmission system incorporating ribbed belts for HVAC Conveying industrial motors agriculture and energy supply markets.

Small sheave pitch diameter inches n. The V shape of the belt tracks in a mating groove in the pulley or sheave so that the belt cannot slip off. Drive torque P2πn 1 Nm.

It can be used without the need to register and there is no software to install. By an Hutchinson skilled engineer experienced in drive belt systems. V-belt is the rubber belt that drives things such as the alternator air conditioning compressor power steering pump and waterpump.

Multiply the correction factors that you found in step 11 with the power rate to find the corrected power rate of the selected standard v-belt. Horsepower HP Pe. Our Application Technology experts offer you free support service regarding the application of our products and also help.

The corrected horsepower rating of one belt is obtained by multiplying the horsepower rating from. Db Diameter of belt. Tension ratio for belt about to slip.

In addition the application allows users to propose more than 100 alternative solutions. P Pitch of Belt. The RPM of the first driven large pulley is transferred to second set small driver pulley and so on.

Other belts Flexonic Conveyxonic. Smallest belt wrap angle α. Smartphone version on Apple Store and Google Play Store.

V-belts trump flat belts with their small center distances and high reduction ratios. Dpi Inner Diameter of pulley. L Belt Pitch Length.

Belt Speed V d x n 382 V. If youre unsure most are rated at 3600. Drive force T 1-T 2 Pv.

Industrial V-belts classical V-belts have been covered in IS 2494 Part 1. The number of belts required for an application is obtained by dividing the design horsepower by the corrected horsepower rating for one belt. Effective pull pounds V.

Torque pounds-inches n. 1993 V-belts - Endless. V W N V P 1 60 09 10 3 2 where.

Distance between teeth Cb circumference of belt. D Pitch Diameter Large Pulley. Optibelt WebCAP is an easy-to-use online drive design and tension calculation tool.

Shaft load F a. The SKF Belt Drive Design Calculations tool version 312 allows field engineers and technical sales people to check the quality of an existing belt drive design on their desktops. The cords transmit the force from the driver to the driven pulley thereby transmit the power.

RPM of small sheave Power HP Tq x n 63025 HP. D Pitch Diameter Small Pulley. Vee Belts V Belts Roy Mech L belt pitch length.

5 V Belt Drive Pulley A Fragment Of The Parametric Model B Fragment Download Scientific Diagram

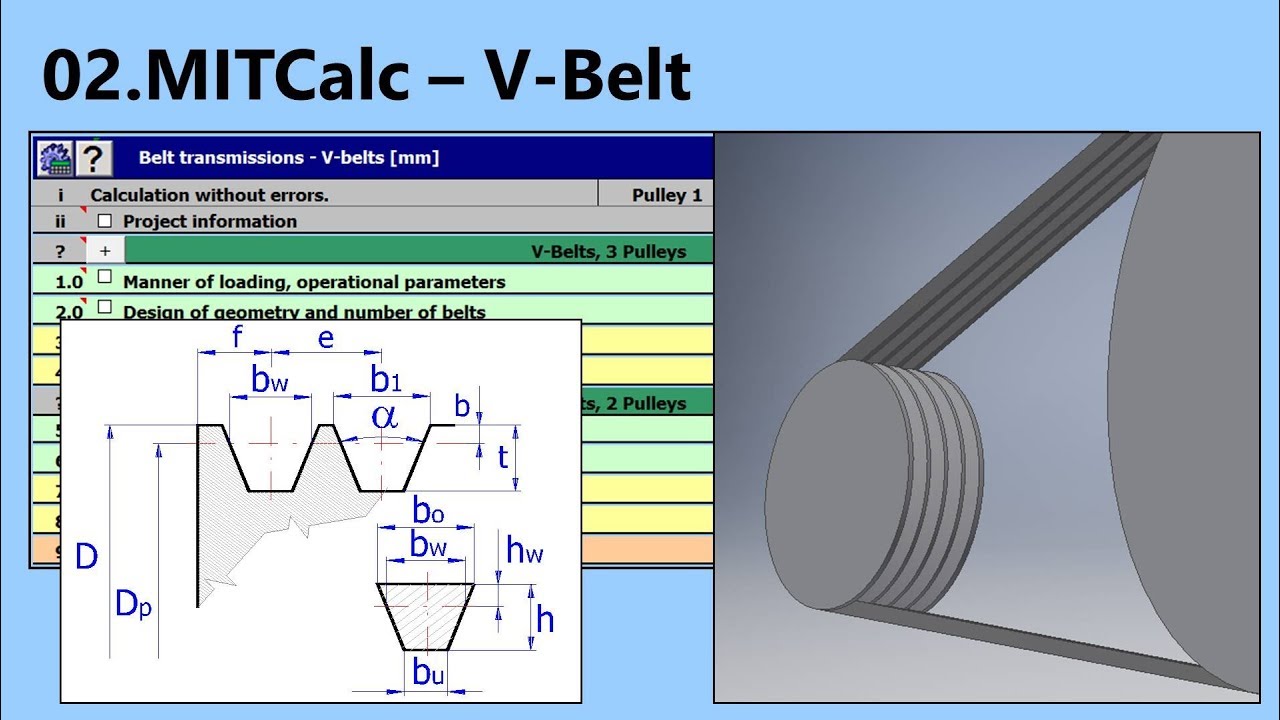

V Belt Calculation And Design Mitcalc 02 Youtube

Solved A 4 Inch Diameter V Belt Pulley Is Mounted On A Shaft Chegg Com

V Belts Design Procedure Youtube

V Belts Design Requirements For Power Requirements Angle Between Sheave

0 comments

Post a Comment