The production technology of PP woven bags. Depending on the device used the cloth can be cut before being printed or can be printed before being cut.

Fibc Vietnam Big Bag Bulk Bag Jumbo Bag Pp Woven Bag Polypropylene Jumbo Bags

31 Heat sealing process Based on the coated tube woven fabric with PP film or BOPP film.

. 1 or 2sets of sewing and cutting machine 2 in 1 machine. It is produced on a loom and made of many threads woven. Using PP woven bags PP non woven bags is becoming increasingly popular with reasonable cost environmental and can be reused.

Through cutting folding the bottom or valve. This includes wire drawing fabric weaving extrusion lamination gravure printing bag forming bag sewing quality testing and customer service. Following we will briefly talk about the investment that the pp woven bag processing factory needs which is oriented by the demand of the middle and low-end woven bags.

We are offering a complete process of pp woven bags manufacturing service main process includes pp extruding circular weaving flexo printing gravure printing lamination bags cutting LDPEHDPE inserting gusseting bags sewing etc. PP spunbond non woven fabric deviation correction - bag opening folding - non-woven fabric folding - bottom inserting - Hot triangle - indentation - Triangle unloading - automatic hot handle - edge sealing - cutting - collection of finished bags - bags and all non-woven fabric bag making processes are completed. At present the most advanced sewing bag technology in the world is not binding but heat sealing and welding.

Learn More Packaging Material Content Technical Article Company News About Mornpackaging MornPackaging is a manufacturing company established in 2003 which is located in Wenzhou. PRODUCTION PROCESS 1- Extrusion The first step is extrusion where to a mix virgin PP resin UV Master Batch Calcium carbonate and colour pigment is melted and shaped into tapes in an Extrusion machine. Automatic sewing can complete printing cutting sewing and other procedures continuously.

According to the different equipment applied it can be. 1 Woven polypropylene bag Uncoated Its production process is. Our manufacturing process of woven polypropylene bags use only pure virgin polypropylene resins and nearly every bag is even visually checked at last before packed.

China PP Woven Sack Bag Making Machine Find details about China PP Woven Bag Manufacturing Line PP Laminated Woven Bag Manufacturing Line from PP Woven Sack Bag Making Machine - Wenzhou Zhuding Machine Co Ltd. The original tubular PP woven fabric is processed into Woven polypropylene bag through printing cutting sewing and other steps. Join Free For Buyer.

Complete quality management systems are strictly followed at each step of the manufacturing process. Mornpackaging is committed to creating customized PP Woven FabricBags and Laminated Woven Bags for worldwide packaging market. According to the different equipment applied it can be cut before printing or printed before cutting.

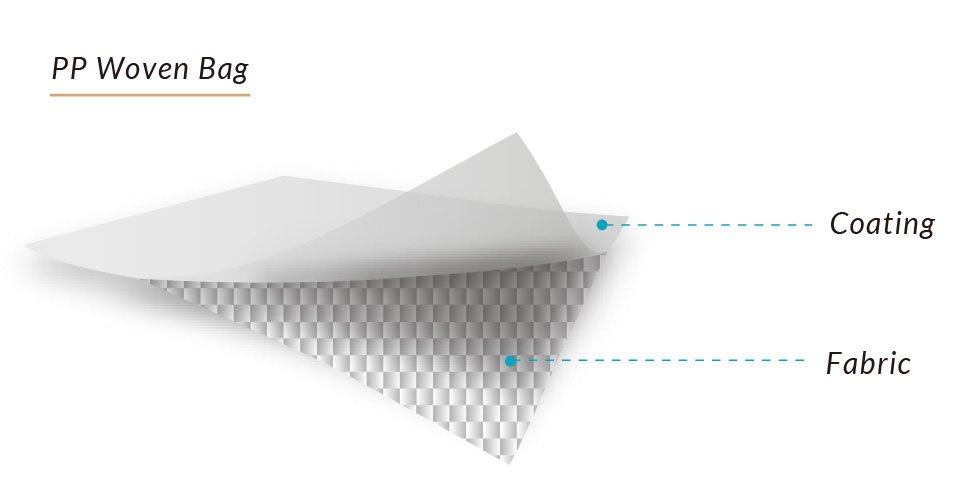

The production technology of composite PP woven bags is to composite or coat the weave fabric coating material and paper or film together. Non-woven bag production process. The obtained tube cloth or piece of cloth can be cut printed stitched to make ordinary seamed bottom bags or it can be punched folded cut printed and stitched to make cement bags.

The tensile durability of the tapes is checked during this processing. Do you know how to produce pp. The original tubular PP woven fabric is processed into woven bag through printing cutting sewing and other steps.

1 PP Woven bags Uncoated Its production process is. Search Products Suppliers Product Directory. Other kinds of bags such as valve bags and.

The production process of this two-in-one three-in-one composite plastic woven bag is to compound or coat woven cloth coating material and paper or film. Around 20000USD per set some model with lower mechanical properties would costs 16000-18000 USDSET. How To Manufacturing PP Woven Bags And Successfully Run The Business In 2020 - Part-1 - YouTube Woven fabric is a textile formed by weaving.

---Caring for your treasures. Woven rolls is printed cut and sewed into woven bags. The roll cloth or sheet cloth obtained can be cut printed sewn and made into common sewing bottom bags and can also be punched folded cut printed sewn and made into cement bags.

Our Process Ganpati Plastfabs manufacturing process of woven polypropylene woven sacks and FIBC bulk bags use only pure virgin polypropylene resins and every bag is quality checked before being packed and shipped.

Pp Woven Bags Raffia The Concept And Process

Pp Woven Bag Hompak Packaging Inc

Best Use Of Polypropylene Woven Bags In Delhi Dns Group Woven Bag Fabric Bags Woven

Manufacturing Process Of Pp Woven Bags Wenzhou Morn Packaging Co Ltd

Pp Woven Bags Manufacturer Supplier Dns Group Woven Bag Woven Bags

Pp Woven Bag Hompak Packaging Inc

Hot Item Custom Luxury Advertising Pp Non Woven Fabric Packing Bag In 2022 Non Woven Bags Luxury Advertising Woven

0 comments

Post a Comment